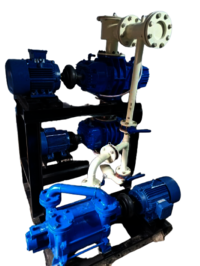

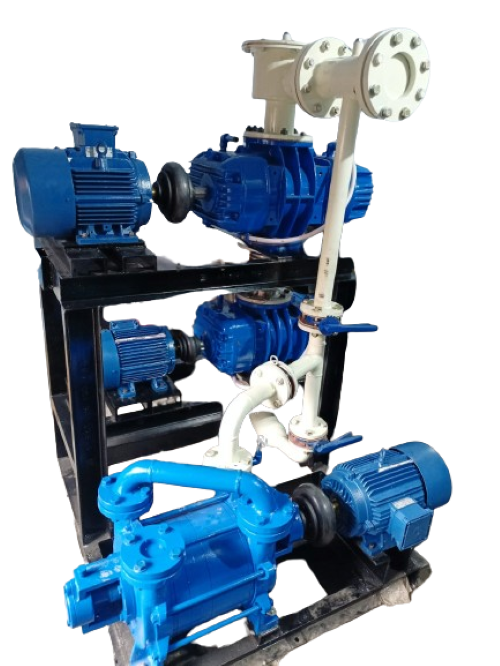

MECHANICAL VACUUM BOOSTER SYSTEM

Product Details:

- Usage For Industrial Area.

- Color BLUE

- Theory Vacuum Pump

- Weight depend on pump Kilograms (kg)

- Product Type WATER RING

- Flow Rate DEPEND ON CAPACITY.

- Inlet/Outlet Depend on vacuum pump

- Click to View more

MECHANICAL VACUUM BOOSTER SYSTEM Price And Quantity

- 455000.00 - 1550000.00 INR/Piece

- 625000 INR/Piece

- 1 Piece

MECHANICAL VACUUM BOOSTER SYSTEM Product Specifications

- Electric

- High Pressure

- DEPEND ON CAPACITY.

- 760 MM/HG.

- Depend on vacuum pump

- For Industrial Area.

- CAST IRON, PSS 304, PSS 316, CSS 304, CSS 316

- BLUE

- Other

- WATER RING

- depend on pump Kilograms (kg)

- Vacuum Pump

- Other

- WATE RING

MECHANICAL VACUUM BOOSTER SYSTEM Trade Information

- Cheque

- 5 Piece Per Month

- 3 Week

- THROUGH VEHICLE.

- All India

Product Description

MECHANICAL VACUUM BOOSTER SYSTEM.

OPERATING MANUAL

Mechanical booster pumps have lobe type rotors driven by timing gears. The rotors counter-rotate with very close clearances between each other And the pump cylinder. The rotors trap a volume of air between each Rotor and the pump cylinder. This is then carried to the exhaust side ofThe pump and discharged.This entrapment occurs four times per revolution. The entrained air is forcedAround the case to the blower outlet. Timing gears accurately position the impellers in relation to each other to maintain the minute clearances vital to the high volumetric efficiency of the pump.

APPLICATION:

Evaporative Concentration, Vacuum Distillation, Polymerization, Crystallization, Vacuum Impregnation, Vacuum Drying, Sterlization, Vacuum Cooling, Object Metallising, Roll Metallisation, Semi-conductor Processing, Manufacture of Vacuum & Microwave Tubes, Manufacture of GLS Automotive & Miniature Lamps, Tube Light Production, Sintering, Brazing, Electron Beam Welding, Heat Treatment, Ionic Nitriding, Tool Coating, Vacuum Casting, Degassing & Refining, Plasma Welding, Evaporation, Sputtering, Space Research and Development.

KEY FEATURES

Booster vacuum levels of backing pumps, thereby reducing process temperature Booster volumetric displacement, thereby reducing Process Time.